The Past and Present of Gears Explained in One Article

The Past and Present of Gears Explained in One Article

As early as 350 B.C., the renowned Greek philosopher Aristotle documented information about gears in his writings. Around 250 B.C., the mathematician Archimedes explained the use of a turbine worm gear in a hoisting machine in his works. Remnants of gears dating back to ancient times are preserved in the Ktesibios Water Clock ruins in present-day Iraq.

Gears also have a long history in China, with records indicating their use as early as 400-200 B.C. The bronze gears unearthed in Shanxi, China, dating back to that period, represent the oldest known gears. The guidance chariot discovered in ancient Chinese artifacts reflects the mechanical device's core mechanism based on gear systems, showcasing achievements in ancient science and technology. During the Italian Renaissance in the late 15th century, the polymath Leonardo da Vinci left an indelible mark not only in cultural arts but also in the history of gear technology. Over 500 years later, gears still retain the prototypes sketched during that era. It wasn't until the late 17th century that people began studying the correct tooth profiles for transmitting motion. After the Industrial Revolution in the 18th century, gear transmission became increasingly widespread in Europe. The development first focused on involute gears and later on helical gears. By the early 20th century, helical gears had gained dominance in practical applications. Subsequent developments included helix gears, circular arc gears, bevel gears, and spiral gears.

Modern gear technology has reached remarkable specifications: gear modules ranging from 0.004 to 100 millimeters, gear diameters from 1 millimeter to 150 meters, power transmission up to 100,000 kilowatts, rotational speeds up to 100,000 revolutions per minute, and the highest circumferential speed reaching 300 meters per second.

Internationally, power transmission gear devices are evolving towards miniaturization, high-speed operation, and standardization. Some features in gear design include the application of special gears, the development of planetary gear devices, and the research on low-vibration, low-noise gear mechanisms.

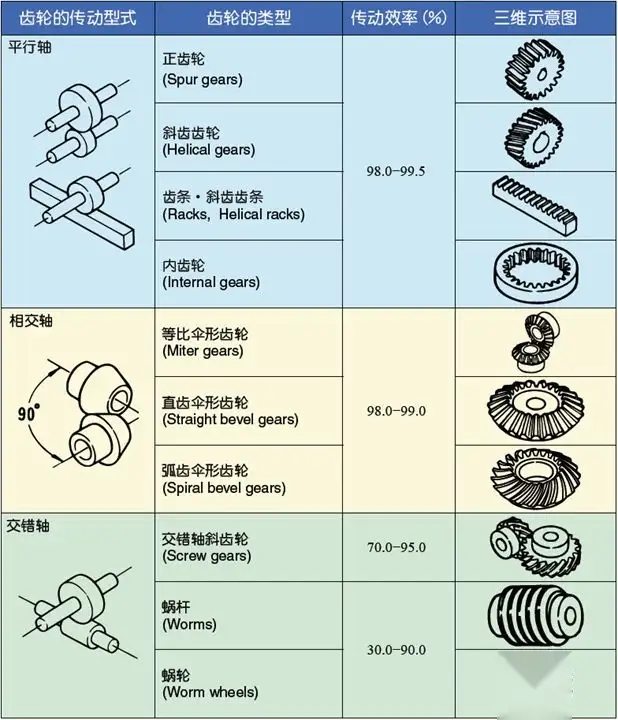

Gears come in various types, commonly classified based on the orientation of gear axes. They are generally divided into three types: parallel-axis gears, intersecting-axis gears, and non-intersecting-axis gears.

Parallel-axis gears: This category includes spur gears, helical gears, internal gears, racks, and helical racks.

Intersecting-axis gears: Examples include straight bevel gears, spiral bevel gears, and zero-degree bevel gears.

Non-intersecting-axis gears: This category encompasses non-intersecting-axis helical gears, worm gears, and quasi-hypoid gears. The efficiency listed in the table above represents the transmission efficiency, excluding losses such as those from bearings and lubrication. Gears in parallel-axis and intersecting-axis gear pairs generally involve rolling, with minimal relative sliding, resulting in high efficiency. In contrast, non-intersecting-axis gears, such as non-intersecting-axis helical gears and worm gears, rely on relative sliding to achieve power transmission, leading to a significant impact on efficiency, causing a decline compared to other gears. Gear efficiency refers to the transmission efficiency under normal assembly conditions. If incorrectly installed, especially in cases of incorrect distances in bevel gear assemblies leading to errors at the bevel intersection point, the efficiency can significantly decrease.