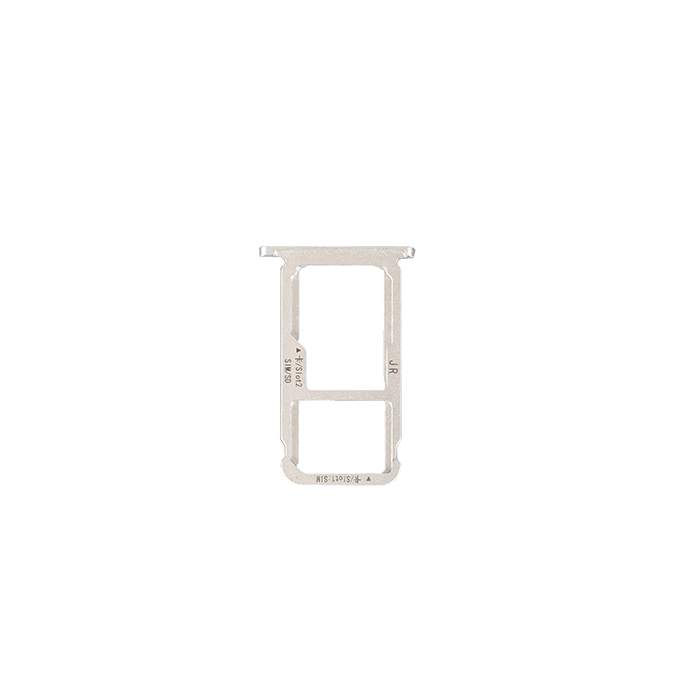

Titanium Injection SIM Card Tray Micro SD Card Tray

- SUNLED

- China

Throughout the entire MIM manufacturing process, strict quality control measures are employed to ensure that the final SIM card trays meet the required specifications.

Titanium Injection SIM Card Tray Micro SD Card Tray

Titanium Injection SIM Card Tray Micro SD Card Tray offer several advantages and highlights compared to traditional manufacturing methods.

MIM allows for the production of SIM card trays with intricate and complex geometries that may be challenging or impossible to achieve using other manufacturing processes. This enables the design of sleek and slim trays that fit seamlessly into modern smartphones and other electronic devices.

MIM offers excellent dimensional accuracy and tight tolerances, ensuring a precise fit for the SIM card within the tray. The high precision contributes to reliable functionality and prevents issues such as loose-fitting cards or misalignment.

MIM parts typically have a smooth and uniform surface finish, reducing the risk of SIM card damage and offering a pleasant user experience when inserting and removing the titanium Micro SD Card Tray.

Overall, the highlights of MIM SIM card trays make them an excellent choice for mobile phone manufacturers seeking high-quality, precise, and durable components that enhance the user experience while maintaining cost-efficiency in large-scale production.

Our workshop: