Exploring the Precision Craft: An Introduction to Machining

Exploring the Precision Craft: An Introduction to Machining

Machining is the meticulous art of shaping raw materials into precise components using various tools and techniques. This fundamental process lies at the heart of manufacturing, playing a crucial role in industries ranging from automotive and aerospace to electronics and medical devices. In this article, we delve into the fascinating world of machining, uncovering its principles, techniques, and significance in modern production.

Understanding Machining:

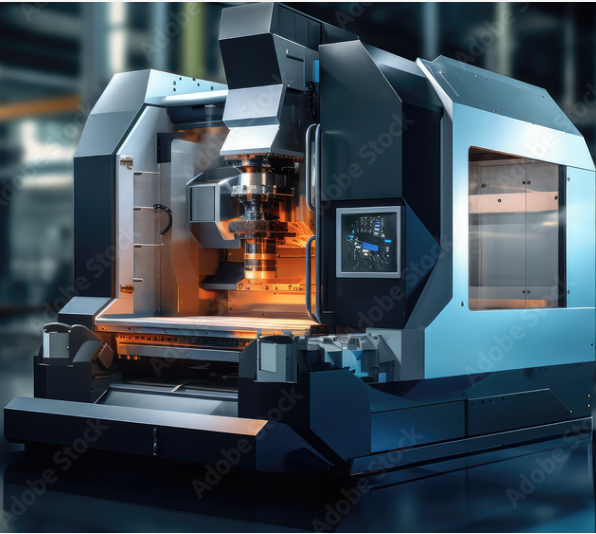

At its core, machining involves the removal of material from a workpiece to achieve the desired shape, size, and surface finish. This process is typically carried out using machine tools such as lathes, milling machines, drills, grinders, and CNC (Computer Numerical Control) machines. These tools are equipped with cutting implements such as drills, end mills, and inserts, which efficiently carve away excess material to create intricate geometries with high precision.

Key Processes in Machining:

Turning: Turning is a machining process performed on a lathe where a cylindrical workpiece is rotated against a stationary cutting tool. This operation is used to create cylindrical parts, such as shafts, rods, and bushings, by removing material from the rotating workpiece.

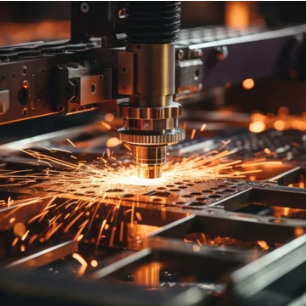

Milling: Milling involves the use of rotary cutters to remove material from a workpiece, which may be held in a stationary position or moved along multiple axes. This versatile process is capable of producing a wide range of shapes, including flat surfaces, slots, pockets, and complex contours.

Drilling: Drilling is the process of creating holes in a workpiece using a rotating cutting tool called a drill bit. This operation is essential for various applications, from creating simple holes for fasteners to producing precise bores for bearings and shafts.

Grinding: Grinding employs abrasive particles to remove material from a workpiece, resulting in highly precise dimensions and surface finishes. This process is commonly used for finishing operations to achieve tight tolerances and smooth surfaces on hardened materials.

CNC Machining: CNC machining utilizes computer-controlled systems to automate the machining process, offering unparalleled accuracy, repeatability, and efficiency. By programming the desired toolpaths and parameters, manufacturers can produce complex parts with minimal human intervention.

Significance of Machining:

Machining plays a vital role in the manufacturing ecosystem, serving as the backbone of modern industry. From prototyping and customization to mass production, machining enables the creation of components with exceptional precision and reliability. Industries such as automotive, aerospace, electronics, medical devices, and defense rely heavily on machining to manufacture critical parts and assemblies that meet stringent quality standards.

Furthermore, machining empowers innovation by enabling the realization of intricate designs and advanced materials. Whether it's producing lightweight aerospace components, high-performance automotive parts, or miniaturized medical implants, machining technologies continue to push the boundaries of what's possible in engineering and design.

Materials Suitable for Machining:

Machining is compatible with a wide range of materials, including metals, plastics, and composites. Some common materials suitable for machining include:

Metals:

Steel: Carbon steel, stainless steel, alloy steel

Aluminum: Aluminum alloys

Brass: Brass alloys

Copper: Copper alloys

Titanium: Titanium alloys

Cast Iron: Gray cast iron, ductile iron

Plastics:

Acrylic (PMMA)

Polyethylene (PE)

Polypropylene (PP)

Polycarbonate (PC)

Nylon (PA)

PVC (Polyvinyl Chloride)

Composites:

Carbon Fiber Reinforced Polymers (CFRP)

Glass Fiber Reinforced Polymers (GFRP)

Kevlar

These materials offer different properties such as strength, hardness, machinability, and thermal conductivity, allowing manufacturers to select the most suitable material for their specific application requirements.

Common Machining Equipment:

In addition to the aforementioned processes, machining utilizes various types of equipment, including:

Lathe: A lathe is a machine tool used for turning operations, capable of shaping cylindrical workpieces with precision.

Milling Machine: Milling machines are versatile tools for removing material from a workpiece to create complex shapes and features.

Drill Press: A drill press is a stationary machine used for drilling precise holes in a workpiece.

Surface Grinder: Surface grinders are used to achieve smooth and flat surfaces on workpieces through abrasive grinding.

CNC Router: CNC routers are specialized machines used for cutting and shaping materials such as wood, plastic, and metal with high precision.

Significance of Machining:

Machining plays a vital role in the manufacturing ecosystem, serving as the backbone of modern industry. From prototyping and customization to mass production, machining enables the creation of components with exceptional precision and reliability. Industries such as automotive, aerospace, electronics, medical devices, and defense rely heavily on machining to manufacture critical parts and assemblies that meet stringent quality standards.

Furthermore, machining empowers innovation by enabling the realization of intricate designs and advanced materials. Whether it's producing lightweight aerospace components, high-performance automotive parts, or miniaturized medical implants, machining technologies continue to push the boundaries of what's possible in engineering and design.

Conclusion:

In conclusion, machining stands as a cornerstone of modern manufacturing, facilitating the transformation of raw materials into functional components with unparalleled accuracy and efficiency. From traditional turning and milling to cutting-edge CNC machining, this intricate process continues to evolve, driving innovation across diverse industries. As technology advances and demands for precision grow, the art and science of machining will remain indispensable in shaping the world around us.