Machining Process

Machining Process

Machining is a manufacturing process that involves the removal of material from a workpiece to create a desired shape, size, and surface finish. This process is widely used in various industries to produce a wide range of components and products, from simple to complex geometries. There are several common machining processes, each with its own specific techniques and tools. Some of the most commonly used machining processes include:

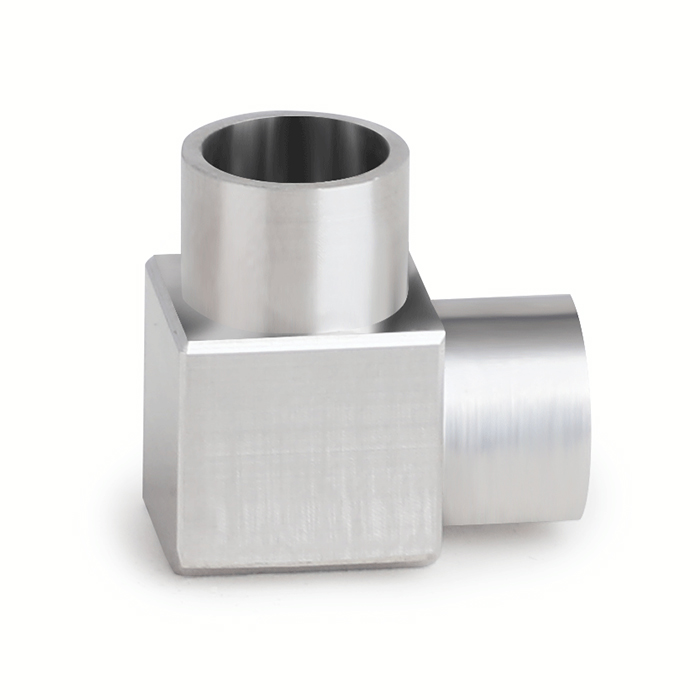

Turning: Turning is a machining process in which a workpiece rotates while a cutting tool is used to remove material from the outer diameter of the workpiece. This process is typically used for creating cylindrical shapes, such as shafts and rods.

Milling: Milling is a process in which a rotating cutter removes material from a workpiece to create flat or contoured surfaces. It is one of the most versatile machining processes and is used to produce a wide range of parts, including slots, pockets, and complex 3D shapes.

Drilling: Drilling is the process of creating holes in a workpiece using a rotating cutting tool called a drill bit. It is a common operation in machining and is used for creating holes of various sizes and depths.

Grinding: Grinding is a precision machining process that involves the use of abrasive particles to remove material from a workpiece's surface. It is used to achieve tight tolerances and excellent surface finishes on parts, such as those in the automotive and aerospace industries.

Broaching: Broaching is a specialized machining process used to cut complex shapes into a workpiece. It involves a cutting tool with multiple teeth that gradually increase in size, allowing it to remove material in a linear fashion.

Electrical Discharge Machining (EDM): EDM is a non-traditional machining process that uses electrical discharges to remove material from a workpiece. It is often used for cutting or shaping electrically conductive materials with high precision.

Laser Cutting: Laser cutting uses a high-powered laser beam to melt, burn, or vaporize material from a workpiece. It is commonly used for cutting sheet metal and other materials with high precision.

Waterjet Cutting: Waterjet cutting involves the use of a high-pressure stream of water (sometimes mixed with abrasive particles) to cut through a workpiece. It is versatile and can cut a wide range of materials, including metals, plastics, and composites.

Ultrasonic Machining: This process uses ultrasonic vibrations to remove material from a workpiece's surface. It is often used for brittle and hard materials like ceramics and glass.

Chemical Machining: Chemical machining involves selectively removing material from a workpiece by using chemical reactions. It is suitable for intricate and delicate parts but requires careful control of the chemical processes.

Machining processes are essential for manufacturing a wide variety of products, from simple consumer goods to complex aerospace components. The choice of the appropriate machining process depends on factors such as the material being worked on, the desired geometry, tolerances, and surface finish, as well as production volume and cost considerations.