Metal Stamping Process

Metal Stamping Process

Metal stamping is a widely used manufacturing process that transforms metal sheets or coils into desired shapes and components.

It involves:

Design and Tooling: Creating part designs and specialized molds (stamping dies).

Material Selection: Choosing the right metal material (e.g., steel, stainless steel ,copper aluminum).

Material Feeding: Loading metal sheets or coils into a stamping press.

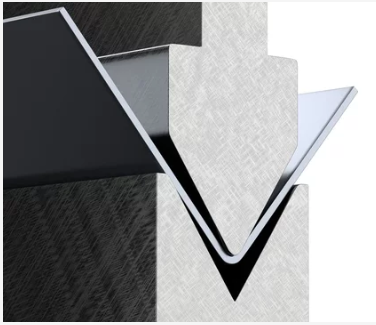

Stamping: Applying immense force to shape and cut the metal into parts.

Ejection and Part Removal: Removing finished parts from the dies.

Quality Control: Ensuring parts meet specifications.

Optional Secondary Operations: Additional steps like welding or finishing.

Packaging and Shipping: Preparing parts for shipment.

Metal stamping is cost-effective, precise, and versatile, making it ideal for mass production of metal parts.