Planetary Gear Transmission Towards High Precision, Intelligence, and Sustainable Development

Planetary Gear Transmission Towards High Precision, Intelligence, and Sustainable Development

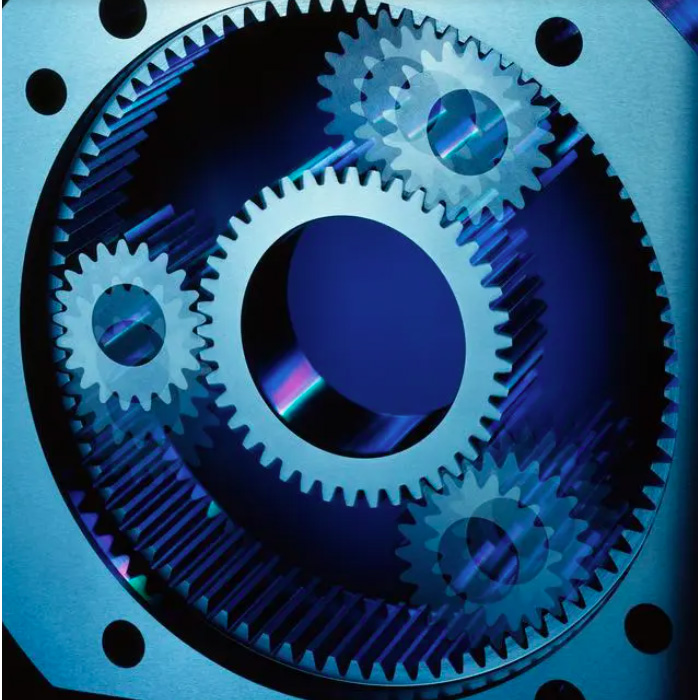

Planetary gears are a common and important mechanical transmission device widely used in various fields. It consists of components such as the sun gear, planetary gears, ring gear, and planetary carrier, offering various advantages such as high transmission efficiency, a wide range of gear ratios, and strong load-bearing capabilities. This article provides a detailed explanation of the working principles, structural features, application areas, and advantages and disadvantages of planetary gears, while also exploring their future development trends.

I. Working Principles of Planetary Gears

Planetary gear transmission is based on the movement principles of planetary gears. The sun gear acts as the driving wheel, while the planetary gears rotate around the sun gear and simultaneously mesh with the ring gear. The planetary carrier connects the planetary gears and the sun gear, providing support and guidance. Different combinations of planetary gears and sun gears can achieve various gear ratios. When the sun gear serves as the input shaft, the ring gear acts as the output shaft, delivering power.

II. Structural Features of Planetary Gears

High Transmission Efficiency: Planetary gear transmissions typically have high transmission efficiency, often exceeding 90%. This is attributed to the multi-point meshing and load distribution characteristics of planetary gears, reducing friction and energy loss in transmission.

Wide Range of Gear Ratios: Planetary gear transmissions can achieve multiple gear ratios through different combinations of sun gears, planetary gears, and ring gears. This adaptability makes them suitable for various applications, from precision instruments to large industrial machinery, with the ability to find the right gear ratio.

Strong Load-Bearing Capacity: Due to the multi-point meshing of planetary gears and sun gears, planetary gear transmissions exhibit high load-bearing capacity. They can withstand significant torque and loads, performing well under heavy-duty conditions.

Compact Structure: The structure of planetary gear transmissions is relatively compact, with a small volume and lightweight design. This makes them widely applicable in limited spaces, especially in situations requiring high gear ratios and compact sizes.

III. Application Areas of Planetary Gears

Planetary gear transmissions find extensive applications in various industries, including but not limited to the following areas:

Automotive Industry: Planetary gear transmissions are widely used in the automotive sector, employed in automatic transmissions and steering systems to achieve different transmission ratios and provide stable power output.

Machine Tools and Industrial Machinery: Planetary gear transmissions play a crucial role in machine tools and industrial machinery, used for driving main spindles, feed systems, conveyor systems, etc., enabling high-precision motion control and load transfer.

Aerospace: Planetary gear transmissions are essential in the aerospace field, employed in critical components such as aircraft and spacecraft engines, landing gear, navigation systems, ensuring reliable power transmission and control.

Marine and Ocean Engineering: Planetary gear transmissions have important applications in marine and ocean engineering, used in propulsion systems, lifting equipment, control systems, meeting high-load and durability requirements in marine environments.

Household Appliances and Consumer Goods: Planetary gear transmissions are commonly found in household appliances and consumer goods. For example, they can be used in household blenders, juicers, sewing machines, providing efficient power transmission and operational control.

Robotics Technology: With the development of robotics technology, planetary gear transmissions play a key role in robotic joints and motion control, offering high precision and stable power output.

Medical Equipment: Planetary gear transmissions are widely used in medical equipment, including surgical instruments, scanning devices, dialysis machines, providing precise gear ratios and reliable motion control to meet the high precision and stability requirements of medical devices.