Aluminum Precision 5 Axis CNC Machining Automotive Parts

- SUNLED

- China

Aluminum automotive components are widely used in the automotive industry to enhance engine performance and efficiency. Specifically, aluminum cylinders are utilized in various types of internal combustion engines, such as gasoline and diesel engines.

Aluminum Precision 5 Axis CNC Machining Automotive Parts

Our automotive components are meticulously crafted from high-grade Aluminum, a material significantly lighter than traditional cast iron. This inherent lightweight quality effectively minimizes the engine's overall weight, resulting in enhanced efficiency and performance.

Moreover, Aluminum boasts innate resistance to corrosion, ensuring the longevity and durability of automotive components even in challenging environments. This attribute further extends the lifespan of these Aluminum CNC Turning Milling components, reducing maintenance needs and costs over time.

The exceptional thermal conductivity of Aluminum Precision machining Automotive Parts enables swift dissipation of heat, effectively regulating temperatures within the engine. This proficient heat management enhances overall engine efficiency and mitigates the risk of overheating.

In the realm of modern automotive engineering, Aluminum Precision Machining Automotive Components stand as pivotal elements. Their incorporation leads to marked improvements in engine performance, fuel efficiency, and environmental sustainability. This pivotal role underscores Aluminum's significance in driving innovation and progress within the automotive industry.

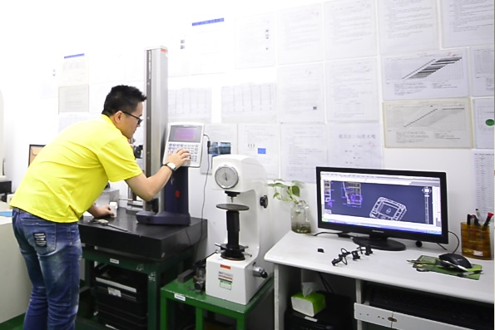

Our factory: