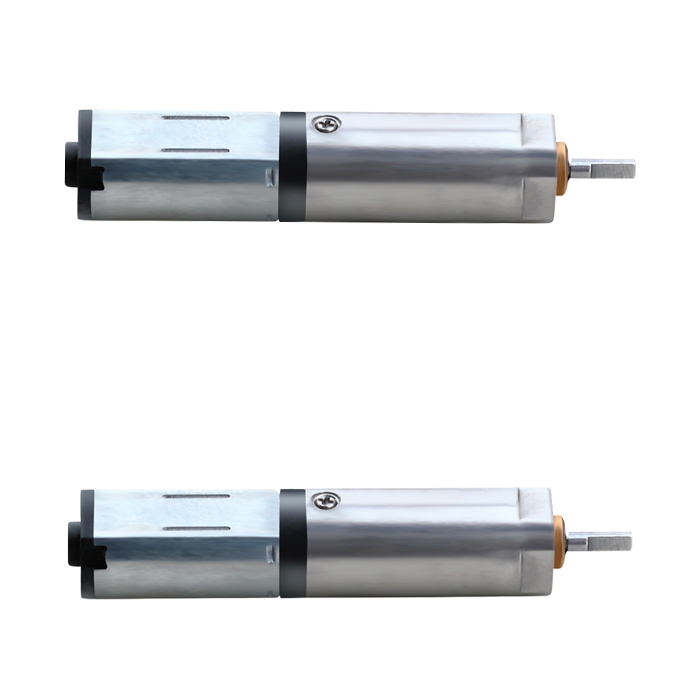

Top Gear Motor

As one of the china electric motor gear reducer factories, we produce customized DC gear motor and customized AC gear motor. And our custom gear motor can be applied in Application Field: Consumer Electronics,Smart Cars,Smart Healthcare,Smart Home,Smart Robots,Personal Care,Industrial Equipment,Communication Technology.

Xiamen Sunled Metal is your trustable reducer gear motor manufacturers in China.

In the dynamic world of machinery and automation, motors play a pivotal role in driving progress. Among the multitude of motors available, gear motors stand out for their efficiency and versatility. This article delves into the realm of gear motors, with a focus on five key categories: Top Gear Motors, Gear Reduction Motors, Planetary Gear Motors, Electric Gear Motors, and Small Gear Motors.

Top Gear Motors:

Top Gear Motors, known for their high-performance capabilities, are engineered to deliver top-notch results across various applications. These motors seamlessly integrate cutting-edge technology and precision engineering, making them ideal for industries where reliability and speed are paramount. Whether it's in automotive manufacturing or heavy-duty machinery, Top Gear Motors set the standard for excellence.

Gear Reduction Motors:

Gear Reduction Motors are designed to provide optimal torque and reduced speed, making them indispensable in applications that require enhanced power and efficiency. These motors utilize a gear train to achieve the desired reduction in speed, ensuring that they can handle heavy loads with ease. Industries such as conveyor systems and material handling benefit significantly from the reliability of Gear Reduction Motors.

Planetary Gear Motors:

Planetary Gear Motors derive their name from their unique gear arrangement, resembling a planetary system. This design allows for an even distribution of load and torque, resulting in increased stability and efficiency. Widely used in robotics, aerospace, and medical equipment, Planetary Gear Motors offer precision and compactness, making them a preferred choice for applications with limited space.

Electric Gear Motors:

Electric Gear Motors represent the convergence of electric power and mechanical precision. These motors are known for their energy efficiency and sustainability, making them ideal for industries that prioritize environmental considerations. From electric vehicles to renewable energy systems, Electric Gear Motors contribute to a greener future by providing reliable and clean power solutions.

Small Gear Motors:

In applications where space is a premium, Small Gear Motors shine. Compact and lightweight, these motors find their niche in industries such as robotics, home appliances, and electronics. Despite their size, Small Gear Motors deliver impressive performance, making them invaluable for tasks that demand precision in confined spaces.

Following is one of our gear box's specification:

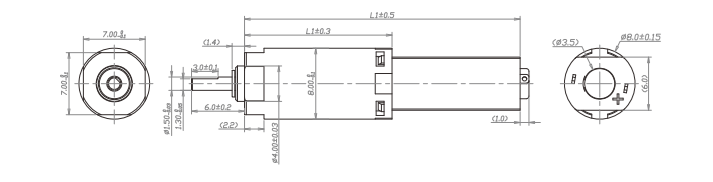

Gear Box for Articulated Robot

SLPD0008 Gearbox Specifications

OD | 8mm | Bearing | Porous bearing | |

Material | Plastic | Axial end play | ≤0.3mm | |

Rotation Direction | cw& ccw | Radial loading on output shaft | ≤0.8N | |

Gear backlash | ≤3°C | Operating Temperature Range | -20°-+85°C | |

Gearbox Stages | 1 | 2 | 3 | 4 |

Reduction Ratio | 4/5 | 13/19 /28 | 47/69/102 /152 | 168/249/369/546/809 |

Max Rated torque of gearbox(gf.cm) | 50 | 100 | 200 | 400 |

Instant torque of gearbox(gf.cm) | 200 | 300 | 600 | 900 |

Gearbox efficiency (%) | 85 | 73 | 65 | 58 |

Gearbox length L1 (mm) | 8.6 | 11.3 | 14 | 16.7 |

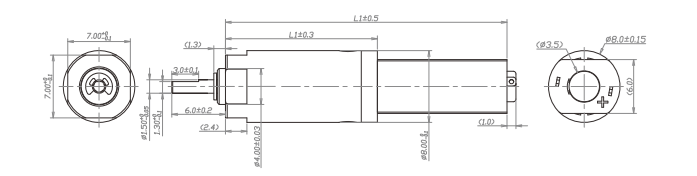

SLMD0008 Gearbox Specifications

OD | 8mm | Bearing | Porous bearing | |

Material | Metal | Axial end play | ≤0.3mm | |

Rotation Direction | cw& ccw | Radial loading on output shaft | ≤2N | |

Gear backlash | ≤3°C | Operating Temperature Range | -20°-+85°C | |

Gearbox Stages | 1 | 2 | 3 | 4 |

Reduction Ratio | 4/5 | 13/19 /28 | 47/69/102 /152 | 168/249/369/546/809 |

Max Rated torque of gearbox(gf.cm) | 250 | 400 | 600 | 750 |

Instant torque of gearbox(gf.cm) | 500 | 800 | 1200 | 1500 |

Gearbox efficiency (%) | 85 | 73 | 62 | 55 |

Gearbox length L1 (mm) | 11.6 | 14.3 | 17 | 19.7 |

OEM/ODM is acceptable!

For more information, please download the attachment!

The world of motors is vast and diverse, and gear motors stand out as a driving force behind countless industrial processes. From the robust performance of Top Gear Motors to the compact efficiency of Small Gear Motors, each category brings its unique advantages to the table. As technology continues to advance, the evolution of gear motors is sure to play a pivotal role in shaping the future of automation and machinery.