Powder Metallurgy Install Tool for Meat Grinder Parts

- SUNLED

- China

We use powder metallurgy, the cost-effective method for manufacturing installation tools, as it reduces the need for machining and minimizes material waste.

Powder metallurgy allows for the production of installation tools with excellent material properties.

Our installation tools meet specific requirements such as hardness, toughness, and wear resistance.

Product Name: Install Tool Meat Grinder Parts

Material: Steel,stainless steel

Process: powder metallurgy, CNC machining, sintering

As a professional metal manufacturing supplier, when we receive our customers' drawings or samples, our primary focus is on finding the most cost-effective processing method that can help them save costs, while ensuring that the technical requirements of the product are not compromised. Our team of engineers, specializing in precision turning, precision machining, powder metallurgy, metal injection molding, and sheet metal stamping, collaborates seamlessly to provide the optimal solution to our customers within 24 hours for their confirmation.

This approach holds true for every order we receive, including the production of installation tools meat grinder parts. For this particular project, we utilized the powder metallurgy process, which proved to be highly efficient, resulting in minimal secondary processing, reduced waste material, and accelerated production speed. Our customers have expressed high satisfaction with our services.

At Sunled Metal Manufacturing, we take pride in our ability to deliver cost-effective solutions without compromising on product quality or technical requirements. Our commitment to excellence and seamless cooperation among our engineering experts make us the ideal partner for all your metal manufacturing needs.

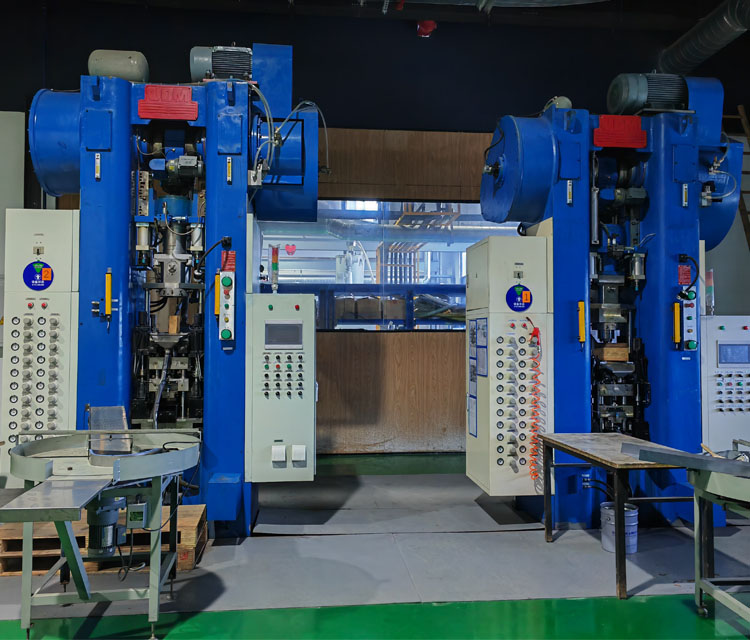

Our powder metallurgy workshop: