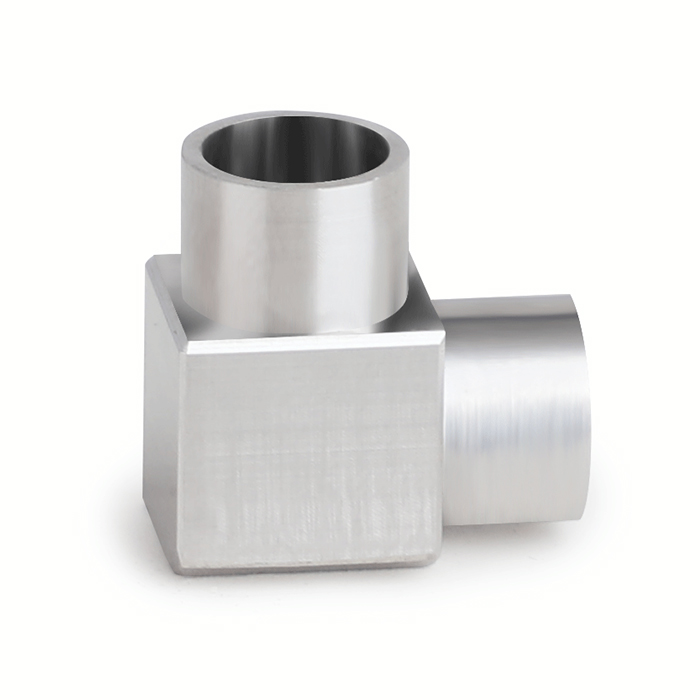

Precision Turning GHT Brass Coupling Assembly

- SUNLED

Our GHT Brass Coupling Assembly's thread machining: Perform precise thread machining to ensure perfect compatibility with other components of the same thread standard, ensuring reliable connections and sealing performance.

Product Name: GHT Brass Coupling Assembly

Material: H58 Brass

Process: mached, turned, milled, lathe

Color: Natural color

Producing GHT Brass coupling assemblies involves the following technical points:

Material selection: Choose high-quality brass material to ensure excellent corrosion resistance and strength of the product.

Precision machining: Utilize precision machining techniques such as CNC machining, turning, milling, etc., to ensure accurate dimensions, uniform shape, and adherence to strict tolerance requirements.

Thread machining: Perform precise thread machining to ensure perfect compatibility with other components of the same thread standard, ensuring reliable connections and sealing performance.

Sealing design: Employ suitable rubber gaskets or sealing washers to ensure reliable sealing performance at the connections, preventing leaks or leakage.

Quality control: Establish stringent quality control systems, including material testing, in-process quality monitoring, and comprehensive inspections of the final products, to ensure that each GHT brass coupling assembly meets the specified quality standards.

Our factory: