Rotary Damper with Torsion Bar

- SUNLED

- China

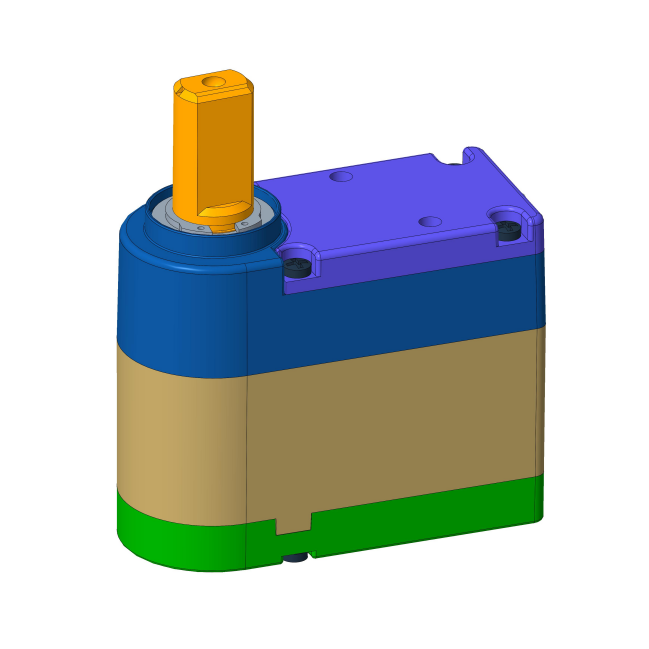

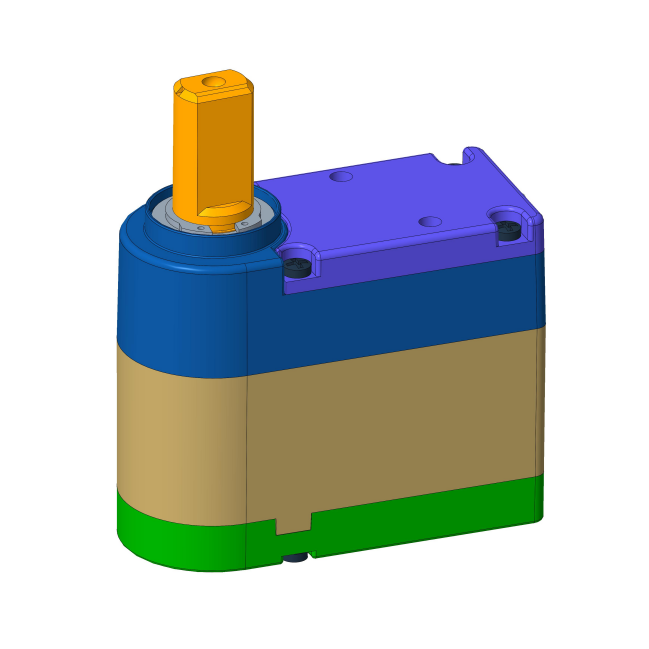

The Rotary Damper with Torsion Bar is a new product from our research and development department, distinguishing itself from commonly found electric rotary dampers in the market. Our Rotary Damper with Torsion Bar offers the following advantages:

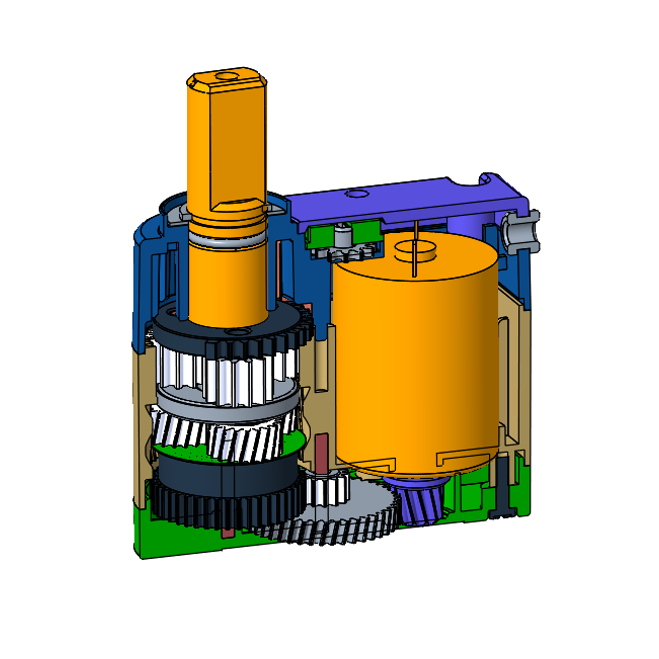

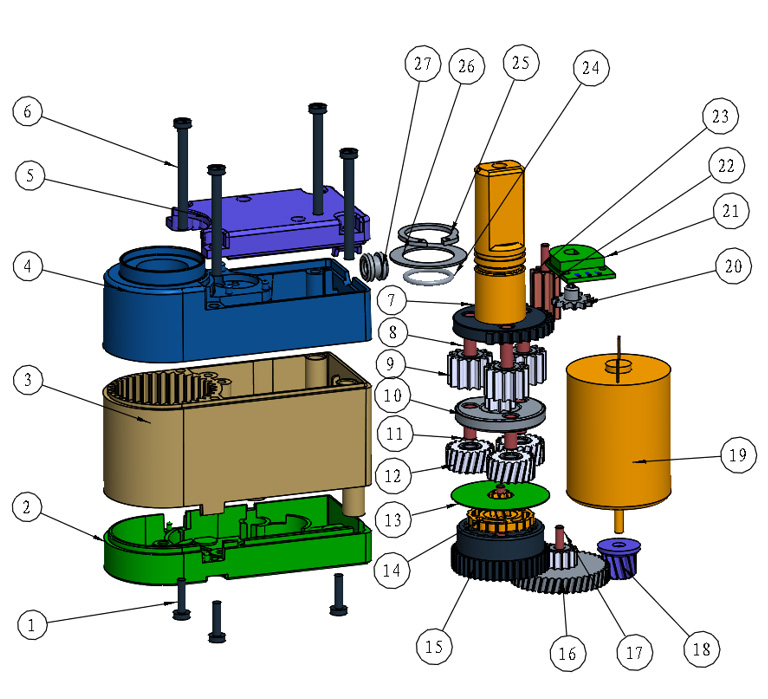

1.Utilizing a helical gear and planetary gear transmission system, the operation is smooth, capable of bearing significant force, with a long lifespan and low noise.

2.The final output consists of powder metallurgy gears, capable of withstanding substantial torque to ensure strength.

3.The enclosed oil storage tank design ensures oil circulates within the gears, preventing spillage onto the motor and circuit board, reducing noise and prolonging lifespan.

4.Replaceable torsion bars allow for customization of the torsion direction according to customer preferences.

Rotary Damper with Torsion Bar

1. Scope

1-1 This product is designed for the automatic hinge of intelligent toilet lids and seats, enabling full automation of opening and closing. This configuration manual provides instructions on the performance and usage conditions of the electric damper.

1-2 Quantity of Application: One unit is used for each toilet lid/seat.

2.Specification

Item | Spec. | Remark |

Rated Voltage | DC12V |

|

Power Consumption | 18W or less |

|

Operating Temperature | 0°C~40°C | Ice free& Dew Free |

Storage Temperature | -10°C~50°C | Ice free& Dew Free |

Operating Humidity | 45~85%RH | Ice free& Dew Free |

Operation Angle | -5°~125° |

|

Rotation Direction | CW | R: CLOSE, L:OPEN DIRECTION |

Load Reversal Direction Load Reversal Direction | CCW | From the output shaft direction |

Output Torque (Rated Load) | 4N·m or more | CCW |

Mechanical Strength (strength of output shaft and mounting components)

| The output shaft and mounting components must not be subjected to external forces exceeding 5 N·m | CCW

|

Motor Type | DC MOTOR | Rare earth Motor |

3.Basic Performance

Item | Spec. | Remark | ||

Insulation Class | Classs A |

| ||

Driving Voltage | DC12V±20% |

| ||

Operating Current | 1.5A or less | Max Current of Motor | ||

No-load Rotation Speed | 13RPM |

| ||

Open Time | 2sec Max | Rated Load, CCW、Duty100% | ||

Close Time | 1sec Min | meet the combined SET control conditions

| ||

Signal Part Voltage | DC5V±5% |

| ||

Signal Output Circuit | Extracted through voltage division with a variable resistor | Total resistance of the variable resistor 10kQ±30% | ||

Driving Circuit | No | Color | Wiring | SET Necessary conditions for control program: 1.Detection of abnormal load: Power should be cut off if abnormal torque (TORQUE) is detected after the switch is turned on. 2.Drive speed control: Implement deceleration before full opening to prevent impact noise. |

1 | Red | MOTOR(-) | ||

2 | Black | MOTOR(+) | ||

3 | Blue | GND | ||

4 | White | OUTPUT | ||

5 | Yellow | Vcc: DC5V | ||

Output Signal | Closed Position 0°:0.5±0.5V | DC5V, including gear mesh clearance | ||

4.Mechanical Performance

Item | R30 Cover | L30 Seat | Remark |

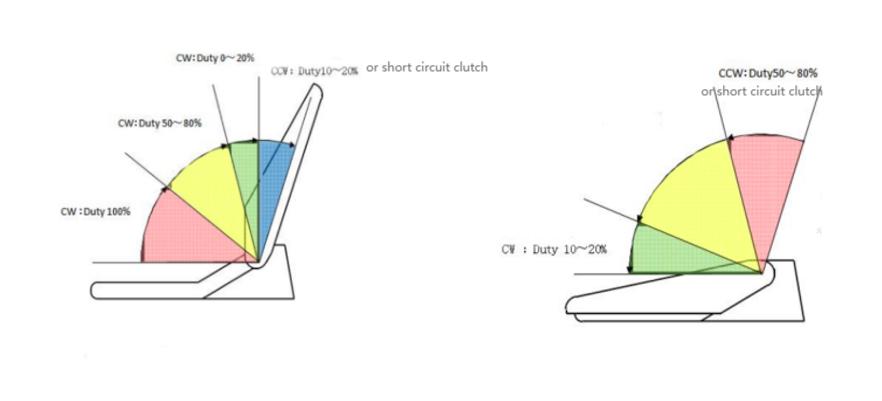

Open/Close Angle | 0°~120° | Refer to the diagram for [] excess angle | |

Operating Direction | Close- CW | Open-CW | Rated Voltage |

Torque (Open) | (40 Kgf.cm Max) | (40 Kgf.cm Max) |

|

Noise | 50dB Max

| 50 dB(A) or less at the position of 1m in front and 1m above | |

Gear Clutch TORQ | (50~100 kgf.cm) | Power Shaft | |

The Rotary Damper with Torsion Bar is a new product from our research and development department, distinguishing itself from commonly found electric rotary dampers in the market. Our Rotary Damper with Torsion Bar offers the following advantages:

1.Utilizing a helical gear and planetary gear transmission system, the operation is smooth, capable of bearing significant force, with a long lifespan and low noise.

2.The final output consists of powder metallurgy gears, capable of withstanding substantial torque to ensure strength.

3.The enclosed oil storage tank design ensures oil circulates within the gears, preventing spillage onto the motor and circuit board, reducing noise and prolonging lifespan.

4.Replaceable torsion bars allow for customization of the torsion direction according to customer preferences.