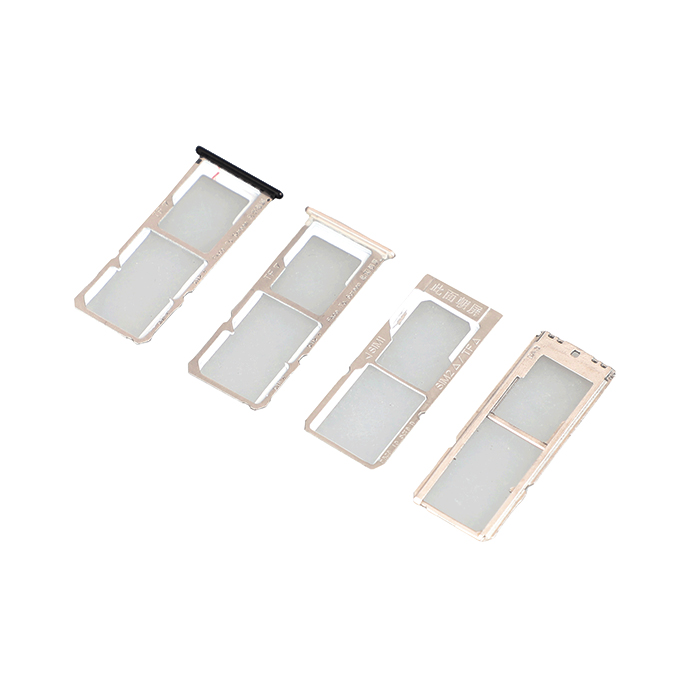

Titanium Metal Injection Molding Dual SIM Card Tray

- SUNLED

- China

After sintering, additional finishing processes such as machining, polishing, or plating is applied to achieve the desired appearance and functionality of the Dual SIM card tray.

Dual Sim card Tray

In the process of manufacturing the Dual Sim card tray, we maintain rigorous quality control throughout the entire production journey. Starting from metal powder preparation, metal injection molding, debinding, all the way to sintering and post-processing, every step is subjected to meticulous scrutiny to ensure the utmost quality of our metal injection molded Dual Sim card holder. Our primary objective is to meet the exacting requirements for seamless card insertion, extraction, and fitting into mobile phones, providing users with a smooth and hassle-free experience.

At each stage of production, our dedicated team adheres to stringent quality standards, employing advanced technologies and precision techniques. By doing so, we can guarantee that the final product is not only functionally superior but also delivers an exceptional user experience. Our commitment to quality and user satisfaction drives us to continually innovate and optimize our processes, making sure that our Titanium Dual Sim card tray aligns perfectly with the needs and expectations of our valued customers.

With our comprehensive quality management system in place, we take pride in producing Sim card trays that are reliable, durable, and seamlessly integrated into modern mobile devices. Through our continuous pursuit of excellence, we strive to exceed industry benchmarks and elevate the overall standard of MIM Dual SIM Card Tray manufacturing, setting new benchmarks for quality, performance, and user satisfaction.

Our workshop: